Food Service

Snack-bars & Cafeterias, Pubs, Pizzerias & Restaurants, Private clubs, Canteens

Examples of application:

• Cleaning and degreasing of workbenches, walls and ceilings.

• Cleaning and defrosting of cooling fins and coils.

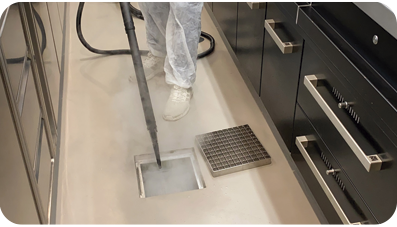

• Elimination of listeria without chemicals in drains and pipes.

• Cleaning and maintenance of ventilation ducts.

• Disposal of food debris.

• Cleaning of dosing systems.

• Cleaning and disinfection of mixing tanks.

• Removal of grease from control panels and electrical panels.

• Sanitization of filters and grids.

• Thorough cleaning of conveyors, chains, belts, rollers and packages.

• Sanitization of refrigeration systems without removing food.

Pathogens and harmful bacteria that can cause serious diseases. The food industry uses strong lines and cleaning and disinfection programs to eliminate all types of bacteria and viruses.

Traditional sanitization is a two-stage process: first, the initial cleaning with water and detergents; second, disinfecting with the help of aggressive chemicals such as chlorine, iodine, quaternary ammonium salts, acid-based substances and formaldehyde.

The adoption of an effective cleaning and disinfection program is crucial to eliminate pathogens from surfaces and equipment. With industrial steam engines, this type of processing becomes faster and easier, since dry steam reduces system and line downtime and saves chemical costs.

The machines also guarantee total hygiene and elimination of microorganisms due to thermal shock.