FOOD INDUSTRY

Confectionery industry, Snack production lines, Dried pasta manufacturers, Ready meal production lines

Examples of application

• Cleaning and degreasing of workbenches, walls and ceilings.

• Cleaning and defrosting of cooling fins and coils.

• Elimination of listeria without chemicals in drains and pipes.

• Cleaning and maintenance of ventilation ducts, removal of food debris.

• Cleaning of dosing systems.

• Cleaning and disinfection of mixing tanks.

• Removal of grease from control panels and electrical panels.

• Sanitization of filters and grids.

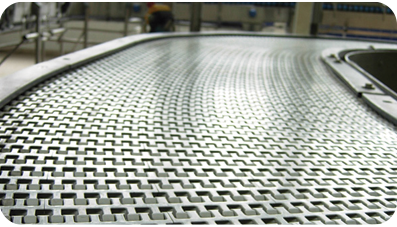

• Thorough cleaning of conveyors, chains, belts, rollers and packages.

• Sanitization of refrigeration systems without removing food.

The sanitation of food processing is a key element to protect the public from pathogens, pathogens and harmful bacteria that can cause serious diseases. The food industry uses strong lines and cleaning and disinfection programs to eliminate all types of bacteria and viruses. Traditional sanitization is a two-stage process: first, the initial cleaning with water and detergents; second, disinfecting with the help of aggressive chemicals such as chlorine, iodine, quaternary ammonium salts, acid-based substances and formaldehyde. The adoption of an effective cleaning and disinfection program is crucial to eliminate pathogens from surfaces and equipment.

With industrial steam engines, this type of process becomes faster and easier, since dry steam reduces system and line downtime and saves chemical costs. The machines also guarantee total hygiene and elimination of microorganisms due to thermal shock.

BAKING

Bakeries, Pastries, Industrial ovens.

Examples of application

• Tunnel ovens and clean ovens.

• Clean and disinfect flat and mesh conveyor belts automatically.

• Clean and disinfect any surface, including all makeup, processing and packaging equipment.

• Disinfect the refrigeration systems.

• Clean the accumulation of grease on floors, walls, ceilings, baseboards, ventilation grilles and dryer.

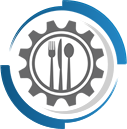

In bakeries there is a constant need to remove residues of flour, mold, oil and grease from kneading machines, rollers, slicers, ovens, conveyor belts, shelves, floors and walls. Traditional cleaning methods use caustic chemicals and large amounts of water that can excessively increase humidity.

Dry steam cleaning is faster and more efficient and penetrates difficult to clean areas, including sensitive electronic equipment and scales.

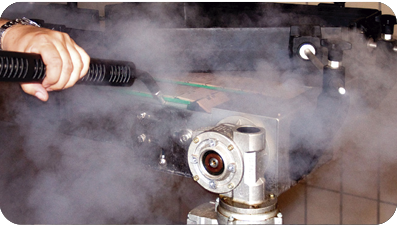

BEVERAGE INDUSTRY

Breweries, Bottling lines for wine, juice and soft drinks, Bottled Water Production, Filling machines

Examples of application

• Hygiene and cleaning of bottling lines and nozzles.

• Elimination of molds and bacteria.

• Cleaning of conveyor belts, chains, belts, rollers and packages.

• Elimination of deposits.

• Polishing of chrome surfaces.

• Cleaning of machinery.

• Disinfection of floors.

Companies specialized in bottling use automated mechanical systems.

The conveyors tend to accumulate dirt, due to the spills of the processed products, residues of lubricants and greases used to keep the system in an efficient state and keep the bands running smoothly. Storage tanks and containers are subject to the accumulation of deposits and incrustations of the processed product in the plant. Saturated dry steam reaches all corners and effectively sanitizes all the components of the plant, avoiding the formation of fungi and mold.

The reduced use of water allows you to clean the control panels and other electrical components.

PACKAGING

Fruit juice packaging lines, Fruits and vegetables packaging line, Pasta packaging lines, Pastry packaging lines

Examples of application

• Stainless steel surfaces.

• Cleaning of conveyor belts, chains, belts, rollers and packages.

• Equipment for wrapping and wrapping.

• Disinfect tanks of any size.

• Polishing of chrome surfaces.

The packaging side of the food processing industry is essential to preserve the integrity, comestibility and shelf life of the product being packaged.

The use of dry steam simplifies the cleaning process since it cleans, sanitizes and dries almost immediately due to the low moisture content of the “dry” steam. Dry steam generators make cleaning faster and much more efficient, since each model is portable, has its own water tank and boiler on board (no water hoses to connect).

EDUCATION

Nurseries and kindergartens, Primary schools and gymnasiums, Universities, Conference centers, Theaters and cinemas

Examples of application

• Hygiene of bathrooms.

• Cleaning and maintenance of ventilation ducts.

• Hygiene of laminated equipment.

• Disinfection of filters and grids.

• Removal of stains and odors from carpets, linings and seats.

• Elimination of viruses, bacteria and fungi.

Saturated dry steam cleaners efficiently handle the professional cleaning and disinfection of busy areas, equipment and places.

These cleaners ensure a high level of hygiene while saving valuable time.

Saturated dry steam cleaners are the most cost-effective technology for environments such as schools, sports centers, saunas and spas. Most of the facilities used in these places require specific and precise maintenance that cannot be supported through the use of traditional cleaning systems.

The machines are lasting ecological investments, due to the high savings obtained by reducing the use of detergents and solvents (about 70%) and the reduction in water consumption by up to 96%.

LODGING AND HOSPITALITY

Hotels, Resorts, B&B, Vacation rentals and Holiday houses, Retirement homes, Campsites, Beach resorts.

Examples of application

• Sanitation of any type of surface.

• Cleaning of parquet and wooden slats.

• Removal of stains and odors from carpets, linings and seats.

• Elimination of chewing gum from coatings and floors.

• In-depth sanitation of bathrooms.

• Polishing of tubes and chrome surfaces.

• Cleaning of elevators, ventilation ducts, windows, mirrors, parquet.

• Cleaning and disinfection of food processing areas.

• Cleaning, sanitization and removal of stains and mold from mattresses.

Hotel accommodations, residences, spas and all kinds of small and large tourist facilities have particular needs in terms of hygiene and hygiene.

Due to the frequency of entry and exit, as well as room service, the cleaning staff is required to be fast and efficient. Hygiene, speed, reduced use of invasive detergents and freshness are characteristics of environments treated with dry saturated steam.

The machines also provide an unparalleled anti-allergic and anti-mite tool and are unsurpassed in carpets, armchairs and in the deep cleaning of ventilation systems.

Environments free of chemicals and fragrances.

Dry steam technology is an eco-sustainable solution that allows you to effectively clean and disinfect without using chemicals. Our steam generators meet the needs of companies in the hospitality sector that are looking for cleaning solutions capable of drastically reducing the use of solvents and chemical detergents.

In this way, they can ensure their customers environments free of chemicals and fragrances, guaranteeing a better air quality in the rooms, with a significant decrease in volatile chemicals that can generate a feeling of discomfort, free of chemicals free of fragrances.

HEALTH CARE

Hospitals and clinics, Ambulatories and offices, First aid centers, Ambulances, Dental clinics, Veterinary clinic, Assisted living residences.

Examples of application

• Sanitization of outpatient clinics.

• Deep cleaning of floors and waiting rooms disinfection of mattresses, pillows and bedding.

• Sanitization of stretchers and rolling chairs.

• Cleaning and disinfection of medical offices, dining rooms and hospital kitchens.

• Cleaning and sanitization of medical cabinets.

• Cleaning and disinfection of food processing areas

• Cleaning, sanitization and removal of stains and mold from mattresses.

Hotel accommodations, residences, spas and all kinds of small and large tourist facilities have particular needs in terms of hygiene and hygiene. Due to the frequency of entry and exit, as well as room service, cleaning staff is required to be fast and efficient.

Hygiene, speed, reduced use of invasive detergents and freshness are characteristics of environments treated with dry saturated steam.

The machines also provide an unparalleled anti-allergic and anti-mite tool and are unsurpassed in carpets, rugs, armchairs and in the deep cleaning of ventilation systems.

CLEANING COMPANIES

Facility management, Company offices, Police stations, Fire stations, Government offices.

Examples of application

• Deep cleaning of floors, parquet, glass, glass, mirrors and contact surfaces with polished chrome.

• Hygiene of bathrooms.

• Cleaning of ventilation ducts, filters and grilles.

• Elimination of chewing gum.

• Removal of stains and odors from carpets, linings and seats.

The professional cleaning and disinfection of crowded places is handled efficiently with saturated dry steam cleaners that guarantee a high level of hygiene and save valuable time.

Machines are long-lasting ecological investments due to the high savings obtained by reducing the use of detergents and solvents (about 70%) and the reduction in water consumption by up to 96%.

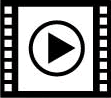

WINE INDUSTRY

Steel tanks, filtration systems, bottling machines, surface filling machines, oak barrels, barrels, and monoblocks.

Examples of application

• Machines for cleaning and disinfecting wine and oil cellars.

• Regeneration in barrels.

• Elimination of deposits.

• Disinfection of steel tanks.

• Disinfection of filters.

• Cleaning of windows, toilets, and floors.

• Elimination of mold, bacteria and parasites leaving a neutral pH on the treated surfaces.

• Cleaning of decanting pipes, accessories, machines, polished chrome surfaces.

Steel surfaces are cleaned optimally and with less effort thanks to the action of steam. The inside of the wine barrels is difficult to reach and clean. With a suitable steam jet system it is possible to efficiently eliminate all types of residues of chemical agents, bacteria and deposits. Steam disinfects each slot covered by microbes and all kinds of dirt that any other traditional cleaning method can reach and eliminate. At the end of the treatment, the surfaces are completely disinfect with any deposit of chemical agents.

In addition to the cleaning of barrels, a cellar has other areas and types of equipment that only steam is able to clean and disinfect efficiently. Among others, these include pipes, flanges, and faucets.

The traditional cleaning methods involve a high consumption of water.

In the process of making a bottle of wine (0.75 l), about 1.5/2 liters of washing water is used. In a medium-sized cellar, 70,000 bottles produced are equivalent to 140,000 liters of water. For example, to clean a barrel you need about 350 liters of water, to clean a tank about 700 liters (depending on the size) and to bottle 500 liters.

FOOD SERVICE

Snack-bars & Cafeterias, Pubs, Pizzerias & Restaurants, Private clubs, Canteens

Examples of application

• Cleaning and degreasing of workbenches, walls and ceilings.

• Cleaning and defrosting of cooling fins and coils.

• Elimination of listeria without chemicals in drains and pipes.

• Cleaning and maintenance of ventilation ducts.

• Disposal of food debris.

• Cleaning of dosing systems.

• Cleaning and disinfection of mixing tanks.

• Removal of grease from control panels and electrical panels.

• Sanitization of filters and grids.

• Thorough cleaning of conveyors, chains, belts, rollers and packages.

• Sanitization of refrigeration systems without removing food.

Pathogens and harmful bacteria that can cause serious diseases. The food industry uses strong lines and cleaning and disinfection programs to eliminate all types of bacteria and viruses.

Traditional sanitization is a two-stage process: first, the initial cleaning with water and detergents; second, disinfecting with the help of aggressive chemicals such as chlorine, iodine, quaternary ammonium salts, acid-based substances and formaldehyde.

The adoption of an effective cleaning and disinfection program is crucial to eliminate pathogens from surfaces and equipment. With industrial steam engines, this type of processing becomes faster and easier, since dry steam reduces system and line downtime and saves chemical costs.

The machines also guarantee total hygiene and elimination of microorganisms due to thermal shock.

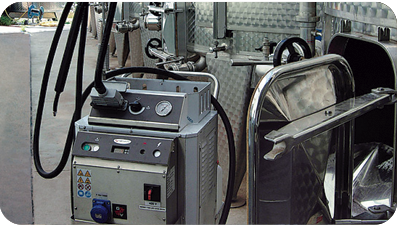

INDUSTRY

Pharmaceutical industry, Coating plants, Mechanical industry, Manufacturing industry, Chemical industry.

Examples of application

• Elimination of fatty waste.

• Cleaning of engines and crankcases.

• Sanitization of filters and ventilation grilles.

• Cleaning of electrical panels.

• Degreasing and polishing of bodies.

• Cleaning of mechanical parts, alloy wheels, filters and grilles.

• Floor cleaning.

• Cleaning of heat exchangers and air conditioners.

• Cleaning of transmission systems and oil sumps.

• Elimination of grease and incrustations of fixed structures and scales.

By using Dry Steam technology for the production of saturated dry steam, the cleaning and degreasing problems present in manufacturing industries can be solved quickly and economically.

When performing the maintenance of machine tools and the pretreatment of individual metal parts, steam is excellent for removing grease. The use of solvents combined with high-pressure water jets can result in serious problems, especially in the elimination of waste and a higher level of toxicity in the work environment. The use of saturated dry steam considerably reduces water consumption.

The removed dirt is encapsulated in the microscopic drops of steam, which fall to the ground due to the effect of gravity.

COSMETICS

Manufacturers of beauty products, Manufacturers of body cleaning products, Soaps and detergent production lines.

Examples of application

• Tanks.

• Elimination of proteins.

• Fillers.

• Conveyor belts.

• Packers

• Cleaning of production lines and bottling plants.

• Eliminate deposits from conveyor belts and gears.

• Disposal of process waste.

• Sanitization of laboratories.

• Cleaning of dispensers.

The production of soaps and detergents can make the work environment and floors slippery. Mixers, boilers and packaging plants are embedded with solidified processing waste, which creates significant safety and hygiene problems.

Traditional water or water jet cleaning machines do not solve these problems and can worsen working conditions.

However, the concentrated force of the steam acts with great precision, even in places of difficult access and the absence of running water makes cleaning fast and safe, even in the presence of electrical circuits.

TRANSPORTATION

Public transport, Sea transport, Land transport, Air transport

Examples of application

• Elimination of odors dry upholstery in a few minutes.

• Cleaning of hard-to-reach places.

• Cleaning of engines and undercarriage.

• Cleaning of transmission systems and oil sumps.

• Glass cleaning without leaving streaks.

The means of transport, both public and private, have particular needs in terms of hygiene and hygiene. Due to the frequency of use, it is required that the personnel and cleaning process be fast and efficient.

Hygiene, speed, reduced use of invasive detergents and freshness are characteristics of environments treated with dry saturated steam.

Dry steam facilitates cleaning to remove stains from factories such as upholstery, floors, and more.

These cleaners not only remove stains without using a lot of water or damaging the material, but they also work faster than extractors and other common alternatives. Steam machines offer a complete removal of stains, and do not damage fabric surfaces.

The machines also provide an unparalleled hypoallergenic and anti-mite tool and are extremely effective in carpets, armchairs and in the deep cleaning of ventilation systems.

SPA & SPORTS

Gyms, Wellness centers, Beautician centers, Hair salons.

Examples of application

• Elimination of viruses, bacteria and fungi.

• Disinfection of contact surfaces.

• Cleaning of windows, mirrors and parquet.

• Hygiene of saunas and Turkish baths, hydromassages, wellness and massage rooms.

• Disinfection of the edges of swimming pools, showers and changing rooms.

• Cleaning of parquet in sports centers.

Health centers and spas are establishments with particular needs, with a daily flow of customers and humid environments at high temperatures that favor the development and proliferation of bacteria and molds. The temperatures reached by industrial dry steam machines guarantee the complete hygiene of these environments.

They are unbeatable for the removal of dirt from tiles and majolica. The exclusive use of steam to sanitize translates into savings and is more environmentally friendly than other methods that are based on the extensive use of disinfectants and chemical agents.

PEST CONTROL

Domestic environments, HO.RE.CA., Industrial environments, Facilities, Transportation.

Ejemplo de aplicación

• It kills germs and bacteria.

• Fights allergies and diseases.

• Protect your loved ones from parasites.

It kills germs and bacteria.

With prolonged periodic use, over time, bacteria and viruses become resistant to chemical treatment.

This can have serious repercussions in environments where hygiene is an absolute imperative, such as in the food and medical industries. Over time, it is necessary to increase the amount of detergents and disinfectants used to maintain the required hygienic results.

This increases the risk of chemical contamination of food products. In addition, since many people are allergic to detergents, their use can have serious effects in hospital environments.

Pathogens are not resistant to the thermal shock of steam cleaning. Research has shown that saturated steam treatment eliminates 99% of bacterial fungi and mold on virtually any surface.

Unlike other cleaning methods, steam can enter all cracks and crevices on the surface. Even with frequent steam cleaning, pathogens cannot generate immunity to thermal shock.